The ice pop production line is an efficient production equipment used to produce popsicles of various flavors and shapes. It consists of a series of automated equipment that can quickly complete popsicle production tasks and improve popsicle production efficiency and quality. The popsicle production line usually includes the following main parts: raw material processing part, mixing part, injection molding part, freezing part and packaging part.

Popsicle Production Line Benifits

Increase productivity

It can achieve continuous, high-speed and accurate popsicles production , greatly shortening the production cycle and saving labor and time costs.

High hygiene standards

Fully automatice, reducing the possibility of human intervention, reducing the risk of cross-contamination, and ensuring the hygiene and safety of the popsicles.

Improve competitiveness

The popsicle production line can respond to market demand faster and launch more diversified and competitive products, occupying a more favorable position in the market.

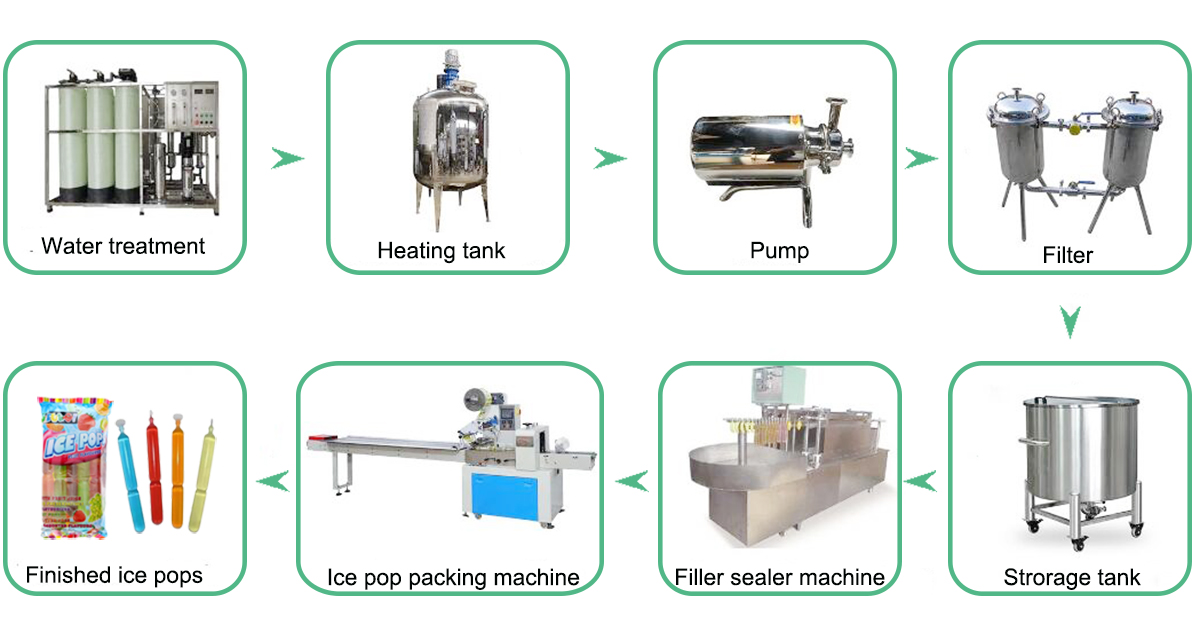

Ice Pops Production Line Working Flow Chart

Water treatment,CIP cleaning,Hot water tank,Emulsification,Cooling,Temporary deposit,Flling and sealing,Sterilization Cooling Dry,Finished product

Water treatment machine is a device used to treat water quality. It can help people remove impurities and pollutants in the water, making the water used for popsicles cleaner and safer. Water treatment machines often include multiple steps such as filtration, disinfection, softening, and removal of heavy metals. These steps can effectively remove bacteria, viruses, organic matter and other contaminants from the water, thereby ensuring the safety of water used for popsicles.

The double filter is used in equipment in the popsicle water treatment system. It can effectively remove impurities and pollutants in the popsicle water and improve the water quality. Duplex filters are usually composed of two filter units, each filter unit has different filter media and filtration precision to achieve different levels of filtration effects.

The injection popsicle filling and sealing machine is suitable for filling and sealing small-mouth plastic soft bottles made of PE material. The mixed raw materials are injected into the popsicle mold to form the shape of the popsicle. It can be used to produce popsicles of various flavors, such as fruit, chocolate, cream, etc. In addition, it can also be used to produce popsicles of various shapes, such as strips, circles, heart shapes, etc.

The popsicle pillow packaging machine uses advanced automation technology to quickly package popsicles into pillow shapes. This machine can be adjusted to accommodate popsicles of different sizes and shapes, allowing for diverse packaging needs. In addition, the popsicle pillow packaging machine also has an intelligent control system, which can realize automated production processes, reduce labor costs and improve production efficiency.

Ice Lolly Production Line Advantages

Auto outfeed;

Auto sealing unit;

Auto gravity filling principle;

Auto squeez unit, auto heating unit;

No bottle no filling, filling process with vacuum empty bottle firstly;

Auto feeding materials from filling hopper with liquid level controller;

In general, the popsicle production line is an efficient production equipment that can quickly complete the production tasks of popsicles and improve production efficiency and quality. Through strict raw material processing, mixing, injection molding, freezing and packaging steps, the popsicle production line can produce popsicles with rich flavors and uniform texture to meet the needs of different customers. If you also want to start a popsicle manufacturing business in the hot summer, you are welcome to leave a message with us online at any time to get more detailed information and a free quotation for the popsicle production line!!