The automatic tomato hot sauce filling production line machine is an efficient and reliable equipment used for mass production of tomato hot sauce. The machine adopts advanced technology and innovative design and can automatically complete filling, sealing and packaging processes, greatly improving production efficiency and product quality.

Tomato Paste Filling Machine Benefits

Greatly improve production efficiency, reduce the need for manual operations, and reduce production costs.

Ensure sauce consistency and quality stability, & improve product competitiveness and market share.

It reduces the labor intensity of employees and improves the safety of the working environment.

Chili Sacue Filling Machine Working Process

The fully automatic ketchup filling line can automatically complete a series of processes such as bottle unscrambbling → filling → capping and capping → aluminum foil sealing → coding → labeling → bottle closing, etc.

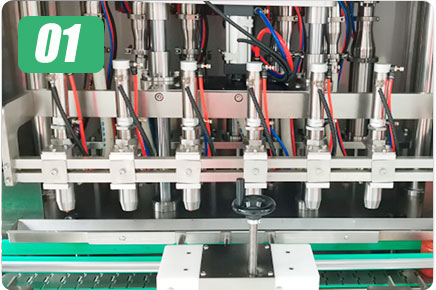

The tomato sauce filling machine is equipped with six filling heads, which can perform multiple filling tasks at the same time, greatly improving production efficiency. Moreover, this equipment also has an automated control system that can automatically adjust the tomato paste /chili sauce filling volume according to preset parameters to ensure the accuracy and consistency of each filling.

The automatic capping machine, also known as the fully automatic in-line capping machine, uses an oscillating cap drop. The automatic sealing and capping machine has a beautiful and elegant appearance, is flexible, has fast capping speed and a high pass rate. It can be applied to capping various sauces, such as tomato paste, chili suace, ketchup and other glass bottled materials.

The aluminum foil sealing machine uses the principle of electromagnetic induction to instantly generate high heat on the aluminum foil on the bottle mouth, and then fuses it to the bottle mouth to achieve the sealing function. The sealing speed is fast and suitable for tomato paste, chili sauce mass production. The all-stainless steel mold-formed shell is beautiful and elegant; easy to use and has good sealing quality.

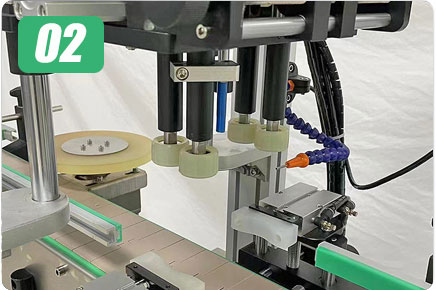

The fully automatic double-sided labeling machine is a multi-functional, high-speed, high-precision labeling machine. Suitable for all kinds of square bottles, round bottles, flat bottles, special-shaped bottles, three/four sides of square bottles, such as oil barrel labeling machine, cosmetics labeling machine, edible oil labeling machine, shampoo labeling machine and other single-side labeling.

Tomato Sauce Filling Machine Parameter

| Name | Fully automatic tomato sauce filling machine |

| Power | 1.5kw |

| Filling accuracy | ±0.5% |

| Specifications | 50- 3000ml |

| Voltage | 220V/380V/380V |

| Packaging Type | Purchase Product Buckets, Bottles, Cans, Tomato Sauce Manufacturing Factory |

| Packaging materials | glass, metal, plastic, ketchup production plant |

| Production capacity | 500ml 1000-1200 bottles/hour, can be adjusted according to customer request |

| Dimensions (L* W*H) | 2000 * 8500 * 2000mm |

Automatic Paste Filling Machine Features

First of all, it can automatically adjust the tomato paste /chili sauce filling speed and capacity to ensure the accurate filling amount of each bottle of tomato hot sauce, avoiding waste and manual operation inaccuracies;

Secondly, the machine uses advanced sealing technology to ensure the sealing and hygiene of each bottle of tomato hot sauce, extending the shelf life of the product;

In addition, the automatic paste filling machine also has an automatic packaging function, which can automatically put the filled tomato hot sauce into the packaging box, improving the packaging efficiency and the appearance quality of the product;

The automatic tomato hot sauce filling production line machine is an advanced equipment and is of great significance for the large-scale production of tomato hot sauce. Its high efficiency, reliability and automation characteristics enable enterprises to improve production efficiency, product quality and competitiveness, and bring new opportunities and challenges to enterprise development.

Recomened Products