Description

The ice pops lolly popsicle packaging machine is suitable for packaging the popsicles filled with juice into plastic bags for the second time and packaging them into pillow shapes. The popsicles packaged by the pillow packaging machine can be sold in batches, and the eating hygiene and safety standards of the popsicles are further improved. The appearance is more beautiful, which can achieve a certain publicity effect and increase the market value of the popsicles!!

Ice Lolly Packing Machine Advantages

Durable

Long service life, durable and not easily damaged;

Improve efficiency

Save labor costs, improve production efficiency and reduce labor intensity;

Widely applicable

It has a wide range of applications and meets the needs of multiple scenarios;

Pillow Packing Machine Parameter

| Model/TYPE | JYD-250 | JYD-350 | JYD-450 | JYD-600 |

| Roll film diameter (mm) | 250mm | 350mm | 450mm | 600mm |

| Bag making length (mm) | B:65-190/120-280 D:90-220 |

B:65-190/120-280 D:90-220 |

130-450 | 120-500 |

| Bag making width (mm) | 30-110mm | 50-160mm | 50-180mm | 100-280mm |

| Product height (mm) | B: MAX.40 D: MAX.55 |

B: MAX.40 D: MAX.60 |

MAX.75 | MAX.110 |

| Packing speed lon/mir) | 40-230 | 40-180 | 30-150 | 20-150 |

| Power(220 50/6010) | 2.4KW | 2.6KW | 2.8KW | 2.8KW |

| Overall dimensions (mm) | 3770*670*1450 | 4020*770*1450 | 4020*820*1450 | 4020*920*1450 |

| Machine weight (KG) | 500KG | 580KG | 650KG | 680KG |

| Other | Aeration devices (nitrogen, oxygen, air, etc.) can be added | |||

| Packaging Materials | Able to heat seal packaging film materials on one side (such as 0PP, CPP OPP composite PE, PET composite PE, and other single-layer or composite packaging film materials) | |||

| Bag shape | Back seal packaging (can be customized) | |||

| Vertical/horizontal sealing texture | Netted packaging/straight grain, netted packaging | |||

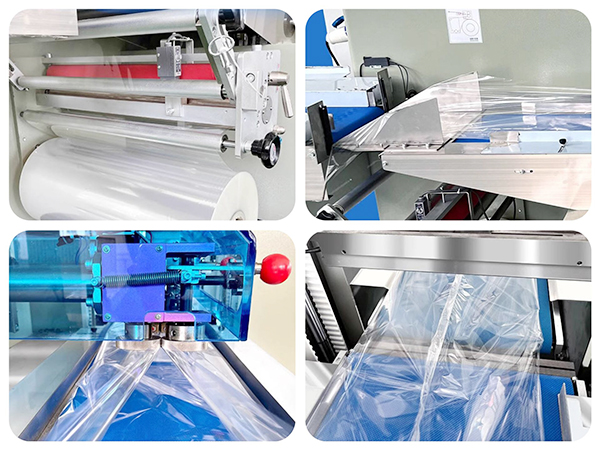

Pillow Packaging Machine Details

End seal cutting area

The cutter holder is made of high-hardness alloy material, which has fast heat transfer and long service life;

Linked film reel

Multi-linked reels are used to coordinate the film pulling process, adapting to more reel materials, and rolling the film more smoothly;

color mark sensor

It uses a high-sensitivity cursor electric eye to accurately track the color blocks of the film roll, effectively preventing deviation during the film roll process;

Multifunctional Chinese-English bilingual touch screen

The human-machine interface controls the entire machine parameter adjustment and machine operation through an intelligent system, making adjustments easy;

Ice Pops Packing Machine Features

●Equipped with a positioning stop function, which can effectively prevent the film from being ironed during shutdown;

●Wide range of packaging, products with multiple specifications can be completed by one equipment, saving expenses for enterprises;

●The forward and reverse tracking adopted improves tracking accuracy, ensures cutting accuracy, and avoids waste of packaging materials;

●The induction anti-cutting function completely eliminates the cutting phenomenon caused by material misalignment, and the packaging yield is high;

●Product parameter memory function, one-click adjustment on the touch screen when changing different packaging products. Convenient and fast, the operation is simple and easy for employees to understand;

●Fully automatic induction of incoming materials to start the machine and stop when there is no material. There is no empty package phenomenon, the material position is offset and misaligned, and the end seal does not cut the material;

Optional equipment

1. Inflating device (nitrogen, air, oxygen, etc.)

2. Connecting device (multiple bags connected)

3. Flower knife/flat knife (end sealing method)

4. Coding machine (ink wheel, thermal transfer printing, laser coding production date, formula, batch number, etc.)

5. Hole punching device (round hole, pinhole, hook hole, etc.)

6. Spray device (spray alcohol, fresh gas, etc.

In general, the pillow popsicle packaging machine is a powerful, efficient and multi-functional equipment that can meet the needs of different customers and improve popsicle production efficiency and product quality. In the future development, pillow popsicle packaging machines will continue to play an important role in promoting the progress and development of the popsicle production industry. If you are also interested in popsicle packaging machines, please feel free to leave a message with us online to get more detailed information and free quotations for popsicle packaging machines!!

Reviews

There are no reviews yet.