The capsule filling process is a very important link in drug production. In this process, the drug is filled into capsules for patients to take. The development and improvement of capsule filling technology has made drug production more efficient and precise.

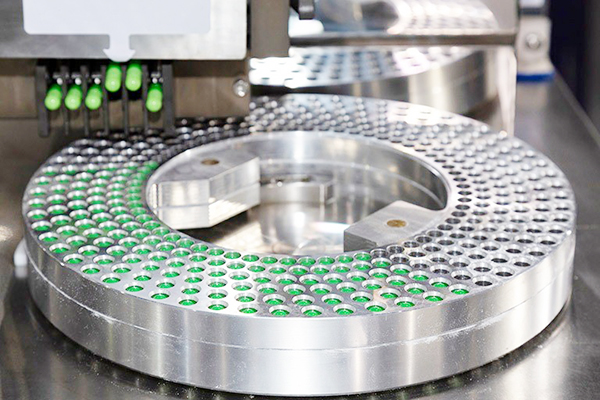

The fully automatic capsule filling machine mainly includes the following links: automatic feeding, subpackaging, filling, sealing, separation, etc.

The fully automatic capsule filling machine is an efficient, precise and safe pharmaceutical equipment, which is widely used in the manufacturing field of various oral solid preparations (such as drugs, biological products, etc.).Through a high-precision control system, the fully automatic capsule filling machine can realize automated production, thereby reducing labor costs, improving production efficiency and ensuring product quality.

The following is the details capsule filling process by the automatic capsule filling machine:

- Automatic feeding

The fully automatic capsule filler automatically supplies capsule carriers and pharmaceutical raw materials to the subpackaging system through a complete mechanical system. - Packaging

The fully automatic capsule filler distributes the powder into each capsule through the packing mechanism. The packing system can accurately control the amount of medicine in each capsule to ensure the accuracy and stability of the medicine. - Filling

In the filling process, the fully automatic capsule filler automatically rotates and vibrates the mechanical parts to fill the powder into the packed capsules. The filling system can accurately control the filling amount of the powder to ensure the uniformity and accuracy of the filling. - Sealing

In the sealing process, the fully automatic capsule filler uses heat sealing technology to seal the capsules so that the powder in the capsules will not flow out or get damp. The high-precision sealing system can ensure the sealing quality of the capsules. - Separation

In the separation process, the fully automatic capsule filler separates the filled capsules from the capsule belt through a mechanical automatic separation device, and the capsules automatically fall into the collection box for packaging.

Here is the capsule filling machine youtube video working process for your reference!!

Capslue Filling Machien Advantages

- Highly automated and high precision;

- Applicable to a variety of pharmaceutical preparations;

- Full-process monitoring can be achieved to ensure product quality;

- The machine parts involved are compact and reasonably designed;

Fully automatic capsule filling machine can greatly reduce labor costs, improve production efficiency, and can accurately control the amount of medicines to ensure the quality of preparations. Therefore, fully automatic capsule fillers are widely used in the pharmaceutical field of oral solid preparations, such as medicines, health products, food, cosmetics, etc., bringing great benefits and advantages to manufacturers. If you are also interested in capsule filling machines, please feel free to leave us a message online for more detailed information!!