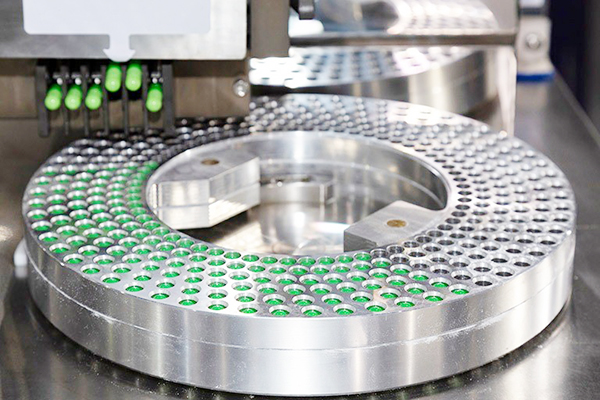

Capsule filling machines are crucial in the pharmaceutical and nutraceutical industries. They streamline the process of encapsulating powders, granules, or liquids into capsules. Proper maintenance of these machines ensures their longevity and efficiency. This guide provides detailed instructions for maintaining your capsule filling machine to keep it running smoothly.

𝐑𝐞𝐠𝐮𝐥𝐚𝐫 𝐌𝐚𝐢𝐧𝐭𝐞𝐧𝐚𝐧𝐜𝐞 𝐈𝐦𝐩𝐨𝐫𝐭𝐚𝐧𝐜𝐞

Regular maintenance of a capsule filling machine is essential to prevent breakdowns and ensure consistent production quality. Without proper upkeep, these machines can experience frequent downtimes, leading to significant productivity losses. Moreover, well-maintained machines produce higher quality capsules, meeting stringent industry standards.

𝑫𝒂𝒊𝒍𝒚 𝑴𝒂𝒊𝒏𝒕𝒆𝒏𝒂𝒏𝒄𝒆 𝑻𝒂𝒔𝒌𝒔

𝐶𝑙𝑒𝑎𝑛𝑖𝑛𝑔 𝑡ℎ𝑒 𝑀𝑎𝑐ℎ𝑖𝑛𝑒

To maintain the capsule filling machine, start with daily cleaning. After every production shift, clean all parts that come in contact with the product. This prevents cross-contamination and ensures product purity. Use suitable cleaning agents recommended by the manufacturer. Make sure all residues are completely removed.

𝐿𝑢𝑏𝑟𝑖𝑐𝑎𝑡𝑖𝑜𝑛

Daily lubrication of moving parts is crucial. Apply the manufacturer-recommended lubricants to all necessary components. This reduces friction and wear, extending the machine’s lifespan. Ensure not to over-lubricate, as excess lubricant can attract dust and other particles, leading to further issues.

𝐼𝑛𝑠𝑝𝑒𝑐𝑡𝑖𝑜𝑛

Conduct a thorough inspection of the capsule filling machine daily. Check for any signs of wear and tear or potential issues. Look for unusual noises or vibrations during operation. Early detection of problems can prevent major breakdowns and costly repairs.

𝑾𝒆𝒆𝒌𝒍𝒚 𝑴𝒂𝒊𝒏𝒕𝒆𝒏𝒂𝒏𝒄𝒆 𝑻𝒂𝒔𝒌𝒔

𝐶𝑜𝑚𝑝𝑜𝑛𝑒𝑛𝑡 𝐶ℎ𝑒𝑐𝑘𝑠

Weekly maintenance should include detailed component checks. Inspect the capsule hopper, filling station, and ejection mechanisms. Ensure all parts are functioning correctly. Tighten any loose screws or bolts to prevent operational issues.

𝐶𝑎𝑙𝑖𝑏𝑟𝑎𝑡𝑖𝑜𝑛

Calibration of the capsule filling machine is necessary for maintaining accuracy. Check and adjust the settings to ensure the machine is filling capsules with the correct dosage. Use calibration tools as specified in the user manual.

𝑆𝑜𝑓𝑡𝑤𝑎𝑟𝑒 𝑈𝑝𝑑𝑎𝑡𝑒𝑠

If the machine includes computerized controls, ensure the software is up-to-date. Manufacturers often release updates to improve performance and fix bugs. Regular updates keep the machine running efficiently and securely.

𝑴𝒐𝒏𝒕𝒉𝒍𝒚 𝑴𝒂𝒊𝒏𝒕𝒆𝒏𝒂𝒏𝒄𝒆 𝑻𝒂𝒔𝒌𝒔

𝐷𝑒𝑒𝑝 𝐶𝑙𝑒𝑎𝑛𝑖𝑛𝑔

Perform a deep cleaning of the capsule filling machine monthly. Disassemble parts as per the manufacturer’s instructions and clean them thoroughly. This prevents build-up that could interfere with the machine’s operation.

𝐶𝑜𝑚𝑝𝑜𝑛𝑒𝑛𝑡 𝑅𝑒𝑝𝑙𝑎𝑐𝑒𝑚𝑒𝑛𝑡

Some components of the capsule filling machine may require monthly replacement. Parts such as gaskets, seals, and O-rings can wear out over time. Replace these parts to maintain optimal performance and prevent leaks or malfunctions.

𝐸𝑙𝑒𝑐𝑡𝑟𝑖𝑐𝑎𝑙 𝑆𝑦𝑠𝑡𝑒𝑚 𝐶ℎ𝑒𝑐𝑘

Inspect the electrical system of the capsule filling machine. Check all wiring and connections for signs of damage or wear. Ensure all sensors and switches are functioning correctly. This prevents electrical failures and enhances machine safety.

𝑩𝒊-𝑨𝒏𝒏𝒖𝒂𝒍 𝑴𝒂𝒊𝒏𝒕𝒆𝒏𝒂𝒏𝒄𝒆 𝑻𝒂𝒔𝒌𝒔

𝐶𝑜𝑚𝑝𝑟𝑒ℎ𝑒𝑛𝑠𝑖𝑣𝑒 𝐼𝑛𝑠𝑝𝑒𝑐𝑡𝑖𝑜𝑛

Every six months, conduct a comprehensive inspection of the capsule filling machine. This includes checking all mechanical, electrical, and pneumatic systems. Engage a professional technician if necessary to ensure a thorough examination.

𝑂𝑣𝑒𝑟ℎ𝑎𝑢𝑙

Depending on usage, a bi-annual overhaul might be necessary. This involves replacing major components that have reached the end of their service life. Overhauls can significantly extend the machine’s operational life and reliability.

𝑇𝑟𝑎𝑖𝑛𝑖𝑛𝑔

Bi-annual training sessions for operators and maintenance personnel are beneficial. Ensure they are updated on the latest maintenance techniques and safety protocols. Well-trained staff can maintain the capsule filling machine more effectively, preventing issues before they arise.

𝐓𝐫𝐨𝐮𝐛𝐥𝐞𝐬𝐡𝐨𝐨𝐭𝐢𝐧𝐠 𝐂𝐨𝐦𝐦𝐨𝐧 𝐈𝐬𝐬𝐮𝐞𝐬

𝐶𝑎𝑝𝑠𝑢𝑙𝑒 𝐽𝑎𝑚

Capsule jams are a common issue. If a jam occurs, stop the machine immediately. Clear the jammed capsules and inspect the filling station for any blockages. Regular cleaning and proper adjustment can prevent jams.

𝐼𝑛𝑐𝑜𝑛𝑠𝑖𝑠𝑡𝑒𝑛𝑡 𝐹𝑖𝑙𝑙𝑖𝑛𝑔

Inconsistent filling can result from calibration issues or worn-out parts. Check the calibration settings and adjust if necessary. Inspect filling nozzles and other components for wear and replace as needed.

𝑀𝑎𝑐ℎ𝑖𝑛𝑒 𝑆𝑡𝑜𝑝𝑝𝑎𝑔𝑒

Unexpected stoppages can be due to electrical or mechanical failures. Check the power supply and all electrical connections first. Inspect mechanical parts for damage or misalignment. Regular maintenance reduces the likelihood of such issues.

𝑪𝒐𝒏𝒄𝒍𝒖𝒔𝒊𝒐𝒏

Maintaining a capsule filling machine involves regular cleaning, lubrication, inspection, and timely replacement of worn-out parts. Adhering to a strict maintenance schedule ensures the machine operates efficiently, reduces downtime, and extends its lifespan. By following these maintenance guidelines, you can ensure your capsule filling machine continues to produce high-quality capsules, meeting industry standards and enhancing productivity.