Description

The toothpaste filling and sealing machine is mainly used to fill the toothpaste from the storage tank into the tube and seal the tube mouth to ensure the sealing and hygienic safety of the toothpaste. As an essential product in daily life, the production of toothpaste requires efficient equipment to ensure production efficiency and product quality. The emergence of toothpaste filling and sealing machines has greatly improved the automation of toothpaste production lines, reduced manual operations, and improved production efficiency and product quality.

Toothpaste Tube Filling Sealing Machine Work Process

Toothpaste Tube Filling And Sealing Machine Working Principle

The automatic toothpaste tube filling and sealing machine is an automated production equipment mainly used for filling and sealing toothpaste tubes. Its working principle is to transport the toothpaste from the storage tank to the filling tube through the automatic control system, then fill the toothpaste into the toothpaste tube, automatically seal it after the filling is completed, and finally discharge the finished toothpaste tube. The entire process is completed automatically without manual intervention, which greatly improves production efficiency and product quality.

Here is the toothpaste tube filling and sealing machine YouTube video working process in our factory for your reference!!

Tube Filling And Sealing Machine Advantages

Toothpaste Filling Sealing Machine Parameter

| Name | Automatic Tube Filling And Sealing Machine |

| Tube Height | 50~200MM |

| Productivity | 20-28 pieces/minute |

| Hose Diameter | 16-50MM |

| Filling range | 6-60ML /10-120ML/25-250ML |

| Dimension | L1630*W1380*H1600MM |

Tube Filling And Sealing Machine Details

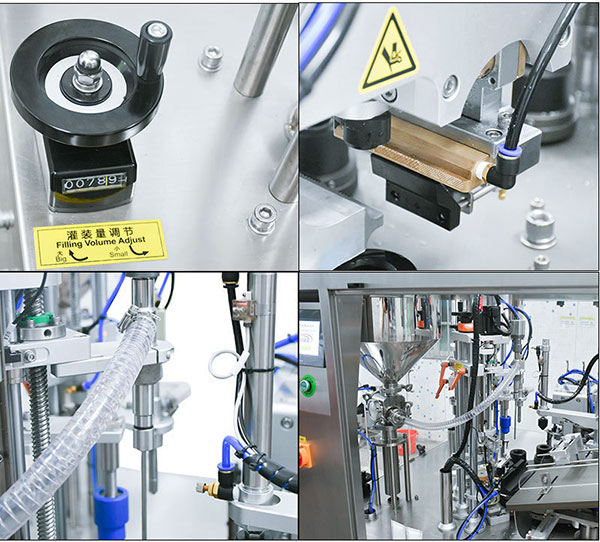

01. Console

It adopts a simple control panel, which is portable and easy to adjust;

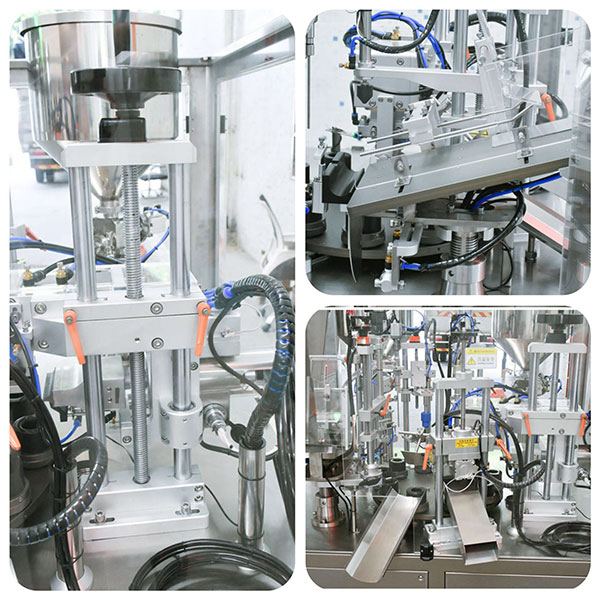

02. Filling head

It can fill liquid paste with no leakage during filling and the filling accuracy reaches +-1%;

03. Tail cutter

Cut off the excess part of the tube, make a straight incision, and cut the tail without drawing;

04. Sensor

Use imported cursor sensor, high-precision sensor, benchmarking, accurate, high-speed, no leakage;

05. Press the tail

The tube tail is heated and formed, and is heated evenly and beautifully without affecting product quality;

06. System

The system uses Panasonic PLC and the transformer uses Omron. The operation is stable, precise, and efficient;

In general, the toothpaste filling and sealing machine, as the key equipment of the toothpaste production line, has the characteristics of accurate filling, firm sealing, simple operation, and convenient maintenance, which is of great significance for improving production efficiency and product quality. With the continuous development of the daily chemical product market, the application scope of toothpaste filling and sealing machines will continue to expand, and its position in the production line will become more important. If you are also interested in toothpaste filling and sealing machines, please feel free to contact us online!!

Reviews

There are no reviews yet.