Aluminum foil bag sealing machine is a common packaging equipment widely used in food, medicine, cosmetics and other industries. Its working principle is to use heat sealing technology to heat the edges of two or more layers of aluminum foil bags so that they are bonded together at high temperature to achieve the effect of sealed packaging.

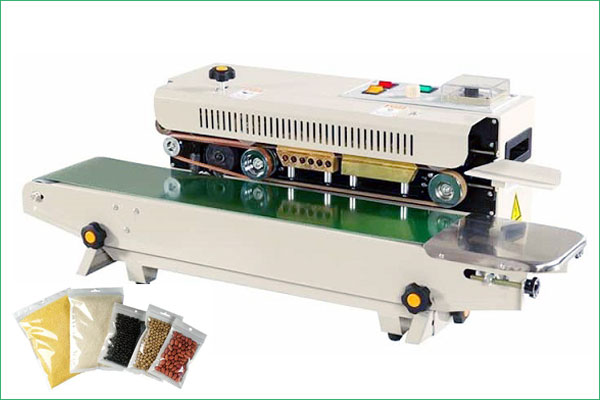

Aluminum foil bag sealing machines usually consist of the following parts: heating element, pressure roller, transmission system and control system.

First, the operator places the aluminum foil bag to be sealed on the machine,

Then starts the machine and the heating element begins to heat the edges of the aluminum foil bag. Once the set temperature is reached, the pressure roller is pressed down to press the edges of the two layers of aluminum foil bags together. The pressure and temperature are maintained for a certain period of time until the edges of the foil bag are completely bonded together.

Finally, the machine will automatically stop and complete the entire sealing process.

Here is the aluminum foil bag sealing machien youtube video working process for your reference!!

The aluminum foil bag sealing machine working principle is simple and efficient, and can quickly complete large-volume packaging tasks. It not only improves packaging efficiency, but also ensures product freshness and quality. In addition, the aluminum foil bag sealing machine also has the advantages of simple operation, convenient maintenance, and good sealing effect, and has been widely used and praised.

In general, the aluminum foil bag sealing machine is a very important packaging equipment and plays a vital role in ensuring product quality and improving production efficiency. With the continuous advancement of technology, the performance and functions of aluminum foil bag sealing machines are also constantly improving, which will bring more convenience and benefits to packaging work in various industries.