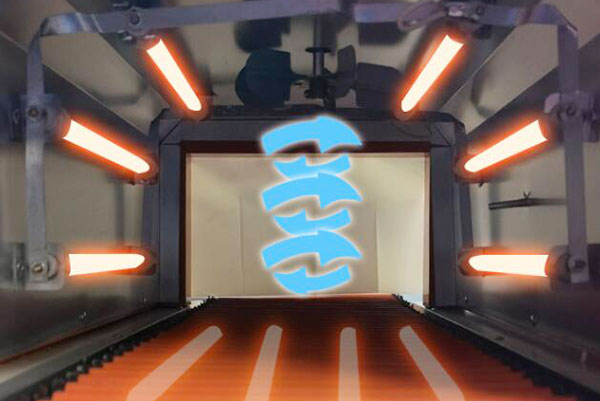

Shrink tunnel wrap machines shrink packaging materials by applying heat and pressure so that they fit tightly against the surface of the product, providing protection and aesthetics. The temperature of the shrink packaging machine is a key factor, which directly affects the quality and effect of packaging.

The temperature of the shrink packaging machine is usually adjusted by the operator according to the requirements of the product and packaging materials. Generally, the shrink tunnel machine temperature range is between 100 and 200 degrees Celsius. The specific temperature setting depends on the features of the product and the type and thickness of the packaging material.

Too low a temperature may cause the packaging material to fail to shrink completely and achieve a tight fit. Too high a temperature may cause excessive shrinkage of packaging materials, or even burn the product or packaging materials. Therefore, the operator needs to make adjustments according to the actual situation to ensure that the temperature is within the appropriate range.

In addition, shrink packaging machines are often equipped with temperature control systems that can monitor and regulate temperature. These systems ensure temperature stability and consistency, thereby increasing packaging reliability and efficiency.

In short, the temperature of the shrink packaging machine is an important parameter, which plays a decisive role in the packaging quality and effect. Operators need to make reasonable temperature adjustments according to the requirements of products and packaging materials to ensure the best packaging effect. At the same time, the use of temperature control systems is also key to ensuring temperature stability and consistency.