Small chemical filling equipment also called chemical liquids filling capping labeling machine is a machine specially used for filling, capping and labeling chemical bottles. This set of packaging equipment integrates the three functions of filling, sealing and labeling, which greatly improves production efficiency, reduces labor costs, and ensures product quality and consistency. It is usually used in small batch production and R&D stages, with efficient and accurate filling and labeling functions.

Chemical Filling Equipment Benifits

Improve efficiency

It can realize the filling, capping and labeling process of liquid chemicals, greatly improving production efficiency;

Wide Applications

It is used for filling, capping and labeling of various plastic bottle types, and is widely used in cosmetics, food, pharmaceutical and chemical industries;

High Safety

Reduces contact with corrosive and other dangerous chemicals during manual operation, causing various safety hazards;

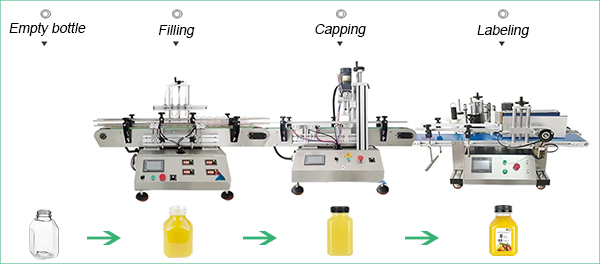

Chemical Lqiuids Packaging Line Working Flow Chart

Bottle sorting, chemical liquids filling, filled chemcial lqiuids bottle cap sealing, filled liquids and capped chemical bottle labeling

| Name | Small Liquids Filling Capping Labeling Packaging Line |

| Production speed | About 2500 bottles/hour |

| Filling range | 10-1000ml (customizable) |

| Gas source pressure | 0.5-0.7MPA |

| Power supply voltage | AC220V 50HZ (optional) |

| Applicable bottle height | 30-300mm (customizable) |

| Equipment material | High-quality stainless steel |

Here is the chemical liquids filling cappping labeling machine working feedback from our customer’s factory for your reference!!

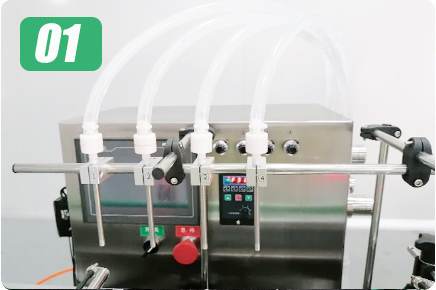

The small four-head liquid filling machine is an efficient and precise filling equipment, which is widely used in food, cosmetics, pharmaceuticals and other industries. The four-head filling speed is faster and the production capacity is higher. It is made of high-quality stainless steel and meets the CMP standard.The filling speed is fast, while ensuring the accuracy and stability of product filling

The stainless steel conveyor belt is a transmission equipment widely used in various industries. It has the advantages of high temperature resistance, non-deformation and corrosion resistance. It is mainly composed of a belt body and a supporting part, which can effectively transfer containers containing filling liquid from one place to another, improve production efficiency and reduce labor costs.

The small four-wheel capping machine is an efficient packaging equipment, which is usually used for the sealing of bottled liquid products. It has automatic capping and sealing functions, which can help manufacturers improve production efficiency and reduce labor costs. This equipment is simple to operate, has high stability, and is suitable for bottles of various specifications.

The desktop automatic labeling machine is used to automatically label products, improve production efficiency and product quality. It can label accurately, and is easy to operate and easy to use. It can not only reduce the labor intensity of workers, but also ensure the consistency and accuracy of product labeling.

Chemical Filling Capping Labeling Machine Advantages

▼Touch screen control, simple and convenient operation;

▼Automatic capping and labeling functions reduce labor costs;

▼Different types of labels and bottle caps can be customized according to needs;

▼Filling speed is adjustable, suitable for pharmaceutical bottles of different specifications;

▼Compact design, small footprint, it is suitable for small laboratories or production workshops;

Chemical liquid filling capping labeling machine is an indispensable filling equipment, which brings many benefits to chemical production enterprises. This chemical liquid filling equipment has a compact structure, small footprint, convenient and flexible use, and low investment cost. It is the best choice for small and medium-sized chemical production plants! If you also want to engage in this business or want to know more detailed information about the chemical filling and packaging line, please feel free to leave us a message online to get more detailed information and free quotes!