Description

The automatic tinplate sealing machine is an efficient and reliable sealing equipment. It uses advanced technology and design to complete the sealing task quickly and accurately. This tin sealer machine is widely used in food, medicine, cosmetics and other industries, providing convenience and protection for product packaging.

Tinplate Sealing Machine Application

It is suitable for sealing various round cans such as tinplate cans, aluminum alloy cans, plastic cans, paper cans, etc. With reliable quality, easy and lightweight operation, it is an essential and ideal equipment for the food, beverage, pharmaceutical, chemical industry, etc. This machine is equipped with two pairs (four) rolling seam sealing wheels, and is a fully automatic can sealing equipment with a fixed can body during rolling and sealing.

Here is the automatic tinplate sealing machine youtube video working process in our factory for your reference!!

Can Sealer Machine Parameter

| Model | YT-980 |

| Material | Stainless Steel |

| Bottle cap height | 80-250mm (Adjustable) |

| Bottle cap diameter | 30-110mm (Adjustable) |

| Bottle diameter | 70-110mm(Adjustable) |

| Capping speed | 50-70 bottles/min |

| Power | 3.3-3.8kw |

| Weight | 104kg |

| Size | 3650(L)*1500(W)*1850(H)mm |

| Voltage | 220V,50Hz |

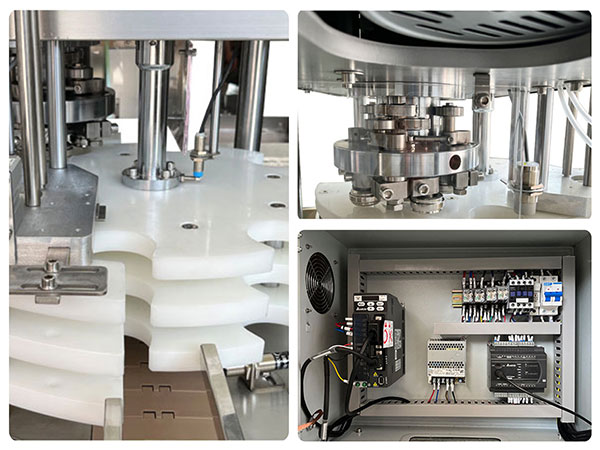

Tinplate Sealing Machine Details

Conveyor

Fully automatic conveying, stable performance, convenient for the next labeling action;

Control Panel

Humanized operation interface, intelligent control, easy to operate in Chinese and English;

Roller

4 sealing shafts work simultaneously, made of Ming material, high hardness, and 304 stainless steel;

Cover

The capping device contains an automatic sensing system, which means no capping if there is no cap, and automatic capping if there is a cap;

Tin Sealing Machine Features

1. The tin sealing appliance uses a frequency converter to regulate speed, which is simple and easy to learn;

2. The tank body is designed not to rotate during the sealing process, the processing precision is high, and the sealing quality is superior to similar domestic products;

3. The sealing wheel adopts four rolling sealing wheels for sealing. The sealing knife and pressure head are made of soldered steel, which will never rust and has excellent sealing performance;

4. It is suitable for sealing various round cans such as tinplate cans, aluminum cans, paper cans, etc. The operation is simple and easy to learn. It is an ideal equipment for food, beverage, pharmaceutical and other industries;

5. The appearance is made of 304# stainless steel, which is durable, can directly contact materials, and is safe. It has high production capacity and automation, saves labor costs, and is suitable as equipment for can sealing production lines;

Reviews

There are no reviews yet.