Description

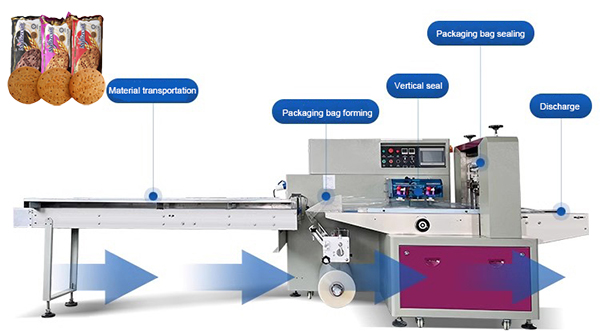

The Automatic Biscuit Pillow Packing Machine is called a “pillow” packaging machine because its working principle is similar to packaging biscuits in pillow-shaped bags. It has the features of high efficiency, stability, and reliability, which can greatly improve the production efficiency of biscuits, reduce labor intensity, and ensure the quality of biscuit packaging. The emergence of pillow packaging machines has saved biscuit companies a lot of manpower and material costs and improved their competitiveness and market share.

Pillow Packing Machine Features

1. Positioning stop function, no knife sticking, no waste of film;

2. Fault self-diagnosis function, fault display is clear at a glance;

3. Human-machine interface, convenient and quick parameter setting;

4. Independent PID control of temperature, better suitable for various biscuit packaging materials;

5. The transmission system is simple, the work is more reliable, and the maintenance is more convenient;

6. High-sensitivity photoelectric eye color mark tracking, digital input of sealing and cutting position, making the sealing and cutting position more accurate;

7. Controlled by three servo systems, the biscuit bag length can be set and cut at any time. There is no need to adjust the unloading speed. It can be completed in one step, saving time and film;

Biscuit Pillow Packing Machine Parameter

| Model/TYPE | ZY-250 | ZY-350 | ZY-450 | ZY-600 |

| Roll film diameter (mm) | 250mm | 350mm | 450mm | 600mm |

| Bag making length (mm) | B:65-190/120-280 D:90-220 |

B:65-190/120-280 D:90-220 |

130-450 | 120-500 |

| Bag making width (mm) | 30-110mm | 50-160mm | 50-180mm | 100-280mm |

| Product height (mm) | B: MAX.40 D: MAX.55 |

B: MAX.40 D: MAX.60 |

MAX.75 | MAX.110 |

| Packing speed lon/mir) | 40-230 | 40-180 | 30-150 | 20-150 |

| Power(220 50/6010) | 2.4KW | 2.6KW | 2.8KW | 2.8KW |

| Overall dimensions (mm) | 3770*670*1450 | 4020*770*1450 | 4020*820*1450 | 4020*920*1450 |

| Machine weight (KG) | 500KG | 580KG | 650KG | 680KG |

| Other | Aeration devices (nitrogen, oxygen, air, etc.) can be added | |||

| Packaging Materials | Able to heat seal packaging film materials on one side (such as 0PP, CPP OPP composite PE, PET composite PE, and other single-layer or composite packaging film materials) | |||

| Bag shape | Back seal packaging (can be customized) | |||

| Vertical/horizontal sealing texture | Netted packaging/straight grain, netted packaging | |||

Horizontal Pillow Packing Machine Details

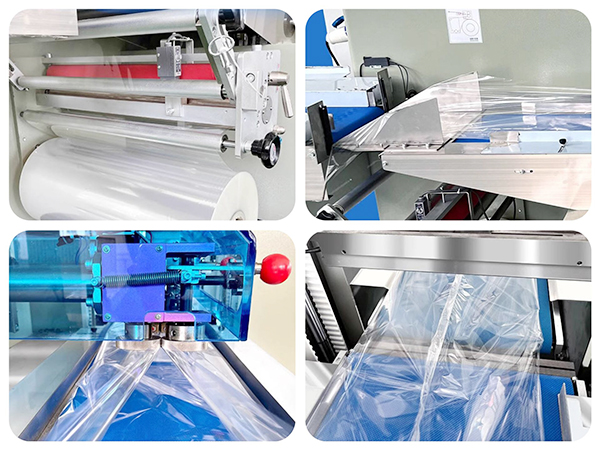

1. Bag-making machine part

Multiple bag sizes can be replaced with multiple bag makers and shared with one machine;

2. Center sealing incision

Independent PID intelligent thermometer can be set to adjust the packaging film temperature to achieve better sealing;

3. Film pulling device

The film-drawing process is not easy to go astray. It is composed of multiple film-penetrating axes. The film-drawing process is smoother and more stable, and the made bags are smoother and more beautiful;

In general, the pillow packaging machine is an efficient, stable, and reliable automatic packaging equipment, that can greatly improve production efficiency, reduce labor intensity and ensure the quality of biscuit packaging. Its emergence has saved biscuit processing companies a lot of human and material costs and improved their competitiveness and market share. With the continuous advancement of technology and the increasing demand for packaging, pillow packaging machines will be more widely used and promoted.

Reviews

There are no reviews yet.