Description

Automatic Capsule Filling Machine is a tool used for automatically producing capsules. It can automatically complete tasks such as capsule filling, sealing, and separation, improving capsule production efficiency and accuracy. More importantly, in the pharmaceutical manufacturing industry, capsules are a common form of pharmaceutical dosage because they are convenient for patients to take and can contain various types of medications.

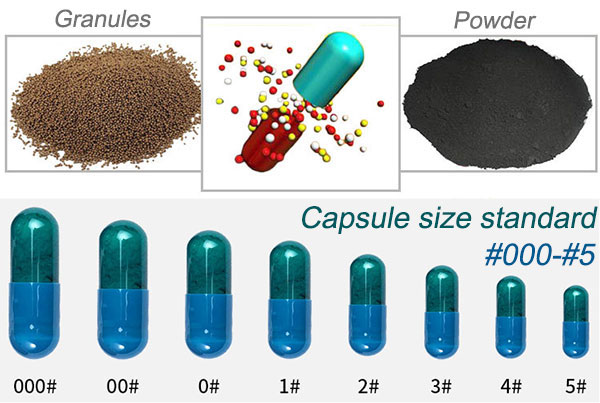

Powders, granules, and other materials can be filled into hollow capsules (000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#, safety capsules A-E)

Automatic Capsule Filling Machine Advantages

Utility model patent turntable;

Suitable for 24-hour production;

High filling accuracy, error <3%;

The large high-precision cam indexing box is continuously stable;

Fully Automatic Capsule Filler Parameter

| Model | NJP-1200C |

| Materials suitable for capsule filling | Powder, granules, pellets, tablets |

| Filling accuracy | Western medicine ±3% Chinese medicine ±4% |

| Capacity | 72000 pcs/h |

| Suitable capsule types for filling | 000,00,0,1,2,3,4,5# |

| Main material | Drug contact parts 316L stainless steel |

| Power supply | 380/220V 50Hz |

| Noise | <75DB(A) |

| Weight | 1100Kg |

| Machine size | 1100×910×2100mm |

| Package Size | Standard wooden box/ 1490×1260×2150mm |

Intelligent Capsule Filler Equipment Working Principle

Automatic capsule filling machines work by completing the filling process through a series of precise steps.

Firstly, the capsule shell and cover sheet are loaded into the machine’s feeding system respectively;

Secondly, the machine automatically opens the capsule shell and injects the precise drug or substance into the shell;

Next, the capsule filling machine will accurately place the cover sheet on the capsule shell to complete the capsule sealing process.

The entire capsule-filling process is automative, reducing human error and labor costs.

Here is the capsule filler YouTube video working process in our factory for your reference!!

Automatic Capsule Filling Machine Features

◆There are pin holes for equipment mold installation, and mold correction is quick and easy;

◆Adopts double accident structure, which is stable under fast operation and complies with GMP requirements;

◆The intelligent capsule filler equipment adopts mold brush cleaning and dust collection devices to increase the capsule loading rate, which can reach 99.99%;

◆There is a special adjustment device for the gap between the dosage plate and the copper plate. There is no need to use a feeler gauge to measure, and the adjustment is quick and easy;

◆The rotating part is fully enclosed and can be equipped with an automatic lubrication system. There is no oil stain on the work surface, which avoids cross-contamination with drugs;

◆The capsule filling machine adopts a German Siemens human-machine interface, PLC programmable controller, LCD output per minute, cumulative output, empty glue and powder status, capsule shortage alarm, automatic shutdown when the powder is not enough, fault diagnosis prompts, etc.;

◆The equipment adopts internal cam transmission, which reduces the center of gravity of the equipment. It has stable high-speed operation and low vibration. In addition, the working noise during high-speed operation is less than 75dB, and the dosage difference is within 3-5% (depending on the powder condition);

The automatic capsule filling machine is an efficient, precise, flexible, and resource-saving equipment, which is of great significance for capsule production in the pharmaceutical industry. Besides, it not only improves production efficiency and product quality but also reduces costs and resource waste. Anyway, if you are also interested in this automatic capsule-filling machine, welcome to contact us freely online!!

Reviews

There are no reviews yet.