Description

The automatic professional tablet pill pressing machine is an efficient and reliable pharmaceutical preparation equipment used to compress pharmaceutical powders into tablets of standard shapes and sizes. The machine has automated features that can improve tablet production efficiency and reduce manual errors.

𝑨𝒖𝒕𝒐𝒎𝒂𝒕𝒊𝒄 𝑻𝒂𝒃𝒍𝒆𝒕 𝑷𝒓𝒆𝒔𝒔𝒊𝒏𝒈 𝑴𝒂𝒄𝒉𝒊𝒏𝒆 𝑾𝒊𝒍𝒍 𝑩𝒓𝒊𝒏𝒈 𝑷𝒉𝒂𝒓𝒎𝒂𝒄𝒆𝒖𝒕𝒊𝒄𝒂𝒍 𝑴𝒂𝒏𝒖𝒇𝒂𝒄𝒕𝒖𝒓𝒆𝒓𝒔 𝑴𝒂𝒏𝒚 𝑩𝒆𝒏𝒆𝒇𝒊𝒕𝒔:

First, it can greatly improve the efficiency of drug production and reduce manual operation time and labor costs;

Secondly, it ensures tablet quality and consistency and reduces variability in the pharmaceutical manufacturing process;

Finally, it can also reduce risks and errors in the pharmaceutical manufacturing process and improve product compliance and safety;

Professional Pill Pressing Machine Features

➤Implement mechatronics;

➤All controllers and operating parts are reasonably arranged;

➤The frequency conversion speed regulating device is used for electrical speed regulation, which is easy to operate, stable in rotation, safe and accurate;

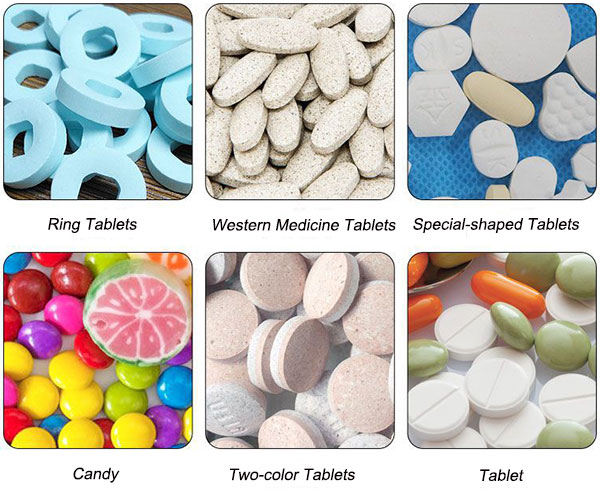

➤Produce circular tablets of various diameters and sizes. Special-shaped tablets of different shapes and specifications can be customized (such as ellipse, star, etc.);

Automatic Pill Press Machine Details

Control station

The controller and operation layout are reasonable and clear, simple and convenient; both pressure and sheet thickness can be adjusted;

Loading station

The hopper and the entire machine are made of 304 stainless steel, and the turntable is specially treated with ball-milled cast iron, with a smooth surface;

Stamping forming station

Various punching dies can be customized and produced, and replacement is simple and convenient; the tableting area is specially treated, and all surfaces are smooth and easy to clean;

Pill Pressing Machine Maintenance Methods:

1. Parts cleaning

①After cleaning the stainless steel and other metal parts with water, wipe them dry and put the evaporator to dry;

②Clean the non-metallic parts and dry them naturally;

2. Daily cleaning

① For daily cleaning, you only need to clean the dust and particles in the main machine. The feeding machinery and mold do not need to be removed.

② If the material produced absorbs moisture, or the material itself has a high viscosity, or the material has oxidizing, corrosive and other chemical properties, the feeding mechanism must be removed and cleaned during daily cleaning, and no material should remain in the mold.

Pill Press Machine Applications

This pill press machine machine is widely used in pharmaceutical factories, pharmaceutical factories, bioengineering, food factories, health products factories, chemical factories, pesticide factories, veterinary drug factories, etc. Granular raw materials with a powder content (above 100 mesh) of no more than 10% can be pressed into tablets of 4 to 20 mm. This machine is not suitable for tableting semi-solid, moist granules, low-melting-point moisture-absorbing raw materials, and granular-free powders.

①Pharmaceutical industry: Chinese medicine tablets, Western medicine tablets, nutrient tablets

②Food industry: candy tablets, coffee tablets, throat lozenges, chocolate beans, seasoning blocks

③Health products industry: buccal tablets, milk tablets, calcium tablets, propolis tablets

④Electronic battery industry: electronic components, button batteries

⑤Chemical industry: camphor balls, aromatic balls, fertilizer tablets, mosquito coil tablets, catalysts, disinfectant tablets, powder cake

⑥Metallurgical ceramics industry: catalysts, metallurgical powder particles, ceramic particles, metal sheets

𝑹𝒂𝒘 𝑴𝒂𝒕𝒆𝒓𝒊𝒂𝒍 𝑹𝒆𝒒𝒖𝒊𝒓𝒆𝒎𝒆𝒏𝒕𝒔 𝑭𝒐𝒓 𝑺𝒖𝒊𝒕𝒂𝒃𝒍𝒆 𝑻𝒂𝒃𝒍𝒆𝒕𝒊𝒏𝒈:

1. Dry powder: The raw materials must be dry powder and the moisture content needs to be controlled within 5%.

2. Fluidity: The raw materials need to have good fluidity (the ideal particle size of the raw material for tableting is between 20 and 60, and a small amount of fine powder is better). If the fluidity of the raw material is not good, it can be solved by making granules (refer to Granulation secrets)

3. Adhesion: Adhesion refers to the ability of the powder to form agglomerates or the powder to stick together through external force factors. If the raw material does not have viscosity, it may need to be improved by adding a binder (such as maltodextrin, starch, sugar, microcrystalline cellulose, etc.)

4. Does not contain a large amount of grease: Raw materials containing a large amount of grease are difficult to form, so the raw materials cannot contain too much grease.

𝑰𝒇 𝒚𝒐𝒖 𝒂𝒓𝒆 𝒏𝒐𝒕 𝒔𝒖𝒓𝒆 𝒘𝒉𝒆𝒕𝒉𝒆𝒓 𝒚𝒐𝒖𝒓 𝒓𝒂𝒘 𝒎𝒂𝒕𝒆𝒓𝒊𝒂𝒍𝒔 𝒂𝒓𝒆 𝒔𝒖𝒊𝒕𝒂𝒃𝒍𝒆 𝒇𝒐𝒓 𝒕𝒂𝒃𝒍𝒆𝒕𝒊𝒏𝒈, 𝒚𝒐𝒖 𝒄𝒂𝒏 𝒄𝒐𝒎𝒆 𝒕𝒐 𝒕𝒆𝒔𝒕 𝒕𝒉𝒆 𝒎𝒂𝒄𝒉𝒊𝒏𝒆 𝒐𝒓 𝒔𝒆𝒏𝒅 𝒕𝒉𝒆 𝒓𝒂𝒘 𝒎𝒂𝒕𝒆𝒓𝒊𝒂𝒍𝒔 𝒂𝒏𝒅 𝒘𝒆 𝒘𝒊𝒍𝒍 𝒕𝒆𝒔𝒕 𝒕𝒉𝒆 𝒎𝒂𝒄𝒉𝒊𝒏𝒆, 𝒕𝒂𝒌𝒆 𝒑𝒊𝒄𝒕𝒖𝒓𝒆𝒔 𝒂𝒏𝒅 𝒔𝒆𝒏𝒅 𝒚𝒐𝒖 𝒂 𝒗𝒊𝒅𝒆𝒐.

The automatic professional tablet pills pressing machine is a pharmaceutical preparation equipment worth investing in. Its efficient, reliable and precise performance will bring huge benefits to pharmaceutical manufacturers. If you are looking for a piece of equipment that will increase your production efficiency and quality, consider purchasing this automatic professional flatbed tablet press.

Reviews

There are no reviews yet.